Fabricated asphalt storage tank

Asphalt is one of the important building materials in the pavement construction of high-grade highway. Due to temporary land acquisition, mobile construction, centralized construction period and other reasons, the storage tank used to store asphalt needs to be moved along with the asphalt mixing plant, quickly disassembled without damage, and transferred for use.

The traditional large-scale asphalt storage tanks mostly use welded fixed tanks. The disadvantage is that when a project ends and the project site changes, the storage tanks can only be cut on site for waste treatment, or the cut materials can be transported to the new project site for re feeding, discharging and welding, which is a great waste of human, material and resources, and is not conducive to civilized construction and environmental protection.

The small overall structure horizontal / vertical insulation asphalt tank provided by the asphalt mixing plant is not suitable for long-distance deployment construction and site tension due to its high transportation cost and large floor area.

The patented technology product of Shengdao Jiaojian -- fabricated (bolt connected) storage tank, which effectively solves the above problems, is widely used in the construction and storage fields of highway, railway, construction, water conservancy, petrochemical, environmental protection, agriculture, military industry, etc. it can store materials individually or combine into a mobile storage tank group / reservoir area according to actual needs.

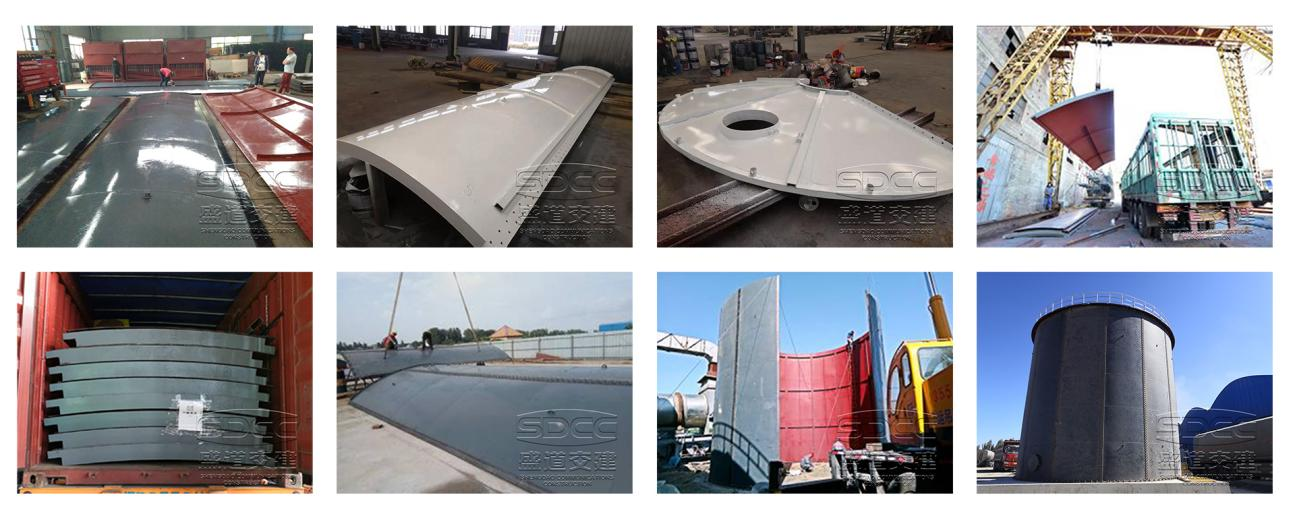

1.Concept of fabricated tanks

The tank body of the storage tank is composed of several steel plate units, which are processed in the factory and transported to the site for assembly. All units are connected and fastened by high-strength bolts. Special structures and sealing materials are used at the connection and fastening parts to ensure their strength and tightness. The single storage volume of fabricated storage tank is 100m ³-6000m ³, It can be used to hold all kinds of liquid materials, powder materials, granular materials, etc.

2. Superior performance of fabricated (bolted) asphalt storage tank

2.1. The overall structure of the storage tank is modular, processed and manufactured in the factory, and the quality is controllable;

2.2 the size of each module meets the requirements of domestic highway and international container transportation standards, with compact structure, saving transportation space and greatly reducing transportation costs;2.3 the structure is scientific and reasonable, the assembly is simple, and the site construction period is short.

2.4. Nondestructive removal and reuse. Practice has proved that the prefabricated storage tank can be reused for more than seven times with one-time investment, which not only saves money, but also realizes the recycling of resources.

2.5. The fabricated storage tank has mature technology, is safe and reliable, is easy to manage, and saves money and worry.

2.6 prefabricated storage tanks are widely used. They can be disassembled and designed as temporary facilities to adapt to temporary land acquisition / lease, mobile construction and emergency projects with concentrated construction period.

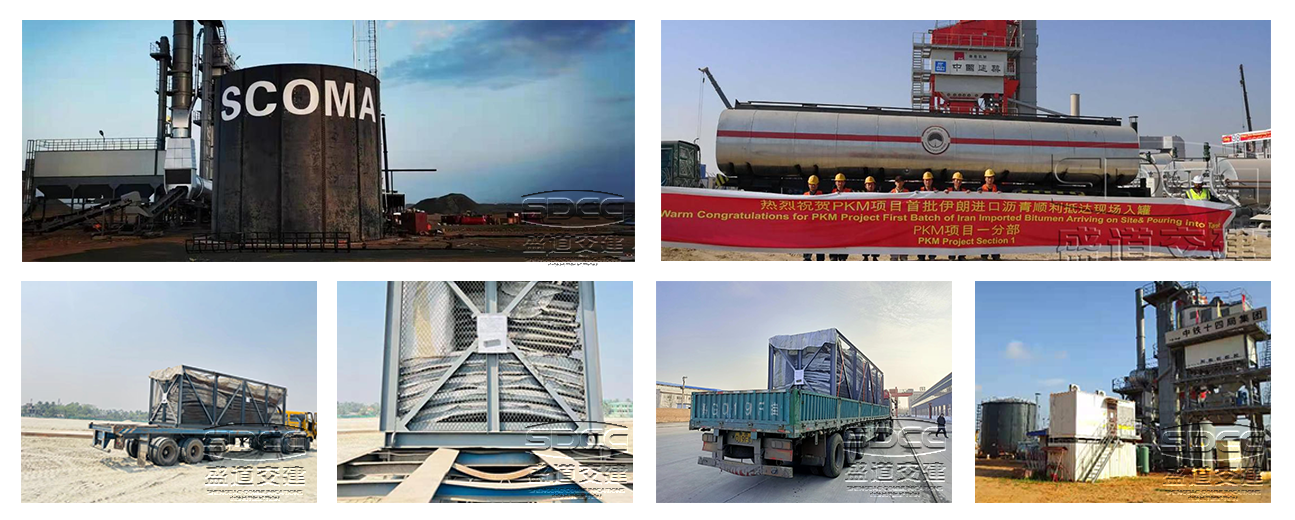

Fabricated tanks are especially suitable for international construction projects!

With the continuous development of international engineering projects driven by the national strategy of the "the Belt and Road", more and more Chinese funded construction units are participating in international projects. The transportation cost of small horizontal tanks is high, and large welded fixed tanks cannot be transported. However, many developing countries have limited construction conditions and do not have on-site processing conditions.

Prefabricated storage tanks are transported by containers to the construction site, and can be quickly assembled and used with less labor. At 500m ³ For example, the storage products can be transported in only one 40 foot container and installed on site by 5 workers in 5 days. It is the best choice for storage tank products in the field of international construction projects.

3. Comparison of economic performance between prefabricated asphalt tank and small-scale integrated structure insulation asphalt tank

With reserves of 500m ³ (traditional small overall structure insulation asphalt tank 50m ³× 10 sets of Prefabricated Asphalt storage tanks 500m ³× 1) as an example.

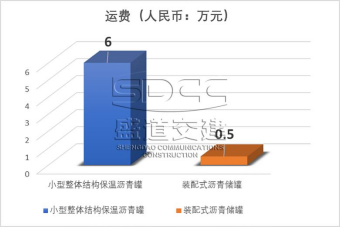

3.1 comparison of transportation costs:

The size of each module component of the Prefabricated Asphalt storage tank meets the requirements of domestic highway and international container transportation standards, with compact structure, saving transportation space and greatly reducing transportation costs. Taking the transportation distance of 500km as an example, the comparison is as follows:

Conclusion: on the premise of the same total reserves and transportation distance, the transportation cost of the assembled asphalt tank with small overall structure insulation asphalt tank can be saved by more than 90%.

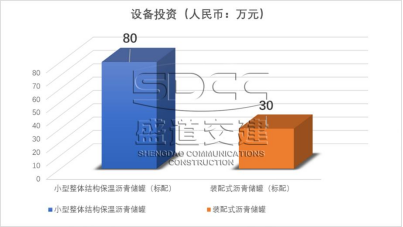

3.2 comparison of equipment investment:

In order to realize the same asphalt reserves (500m³), the traditional small integral structure insulation asphalt tank single reserves of 50 m³, need 10 (standard), while the prefabricated asphalt storage tank only need 1 (standard), the investment cost is as follows:

Conclusion: The assembled asphalt storage tank saves more than 60%.

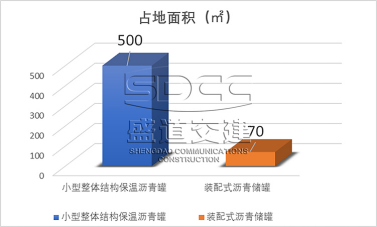

3.3. Comparison of land area:

With the same asphalt reserves (500m³), 10 small overall structure insulation asphalt tanks are needed, while only one prefabricated asphalt storage tank, the area is as follows:

Conclusion: For some projects with difficult land acquisition, mountain construction and temporary land acquisition, it is particularly important to store more asphalt with less sites.The prefabricated asphalt storage tank saves nearly 90% of the small overall structure insulation asphalt tank.